Engineering.com x 3DEXPERIENCE® Cloud Research Report based on Global Survey

Simulation-driven design strategies promise engineers and designers the ability to get products to market better and faster. The goal of unified modeling and simulation, MODSIM, within product development workflows is to streamline the process for optimization. As a result, teams go through more iterations to ensure final designs are as competitive as possible.

Many CAD and CAE software developers propose that the promise of simulation—to get products to market better and faster—can only become reality when design and analysis are integrated throughout the development cycle. To understand these ideas, engineering.com conducted a survey, sponsored by Dassault Systèmes, to learn more about the role simulation plays in development cycles.

Unified Modeling and Simulation (MODSIM) to Contain Prototyping Costs

Since physical prototypes are costly and time consuming, this suggests that there is room in organizations to streamline the processes between design, validation and iteration by utilizing MODSIM strategies. This is supported by the fact that only 38% of respondents validate while drafting or during early design.

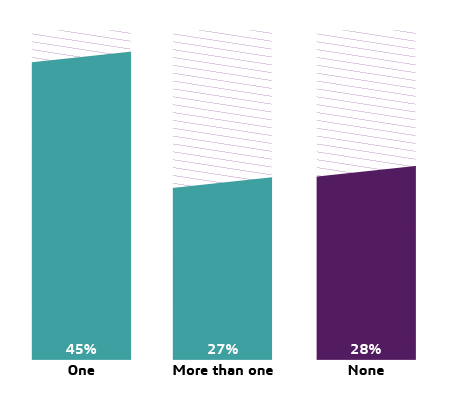

Just under half of engineers use a single prototype. This makes sense, as it is often recommended to verify and validate simulations with at least one prototype. And having a single prototype still fits the ‘build it right the first time’ philosophy of MODSIM and simulation-led design.

Interestingly, 28% of engineers avoid physical prototypes. This suggests they have already validated the simulations, or their products cannot be easily or economically tested. Most respondents (66%) are in favor of running more simulations over creating prototypes. However, just over half (56%) are using MODSIM or unified modeling and simulation design tools.

Discover more about how to use MODSIM to reduce development cycles by downloading the report.