Using 2D drawings to design plant layouts can make it hard to position machinery accurately, to visualize the space needed to safely operate and maintain equipment, and to communicate important operational information to non-technical stakeholders. If you’re looking to improve this error-prone process that can translate into unplanned downtime and expensive rework if not done right the first time, 3D plant and process design software could be the solution to avoid production delays and budget overruns.

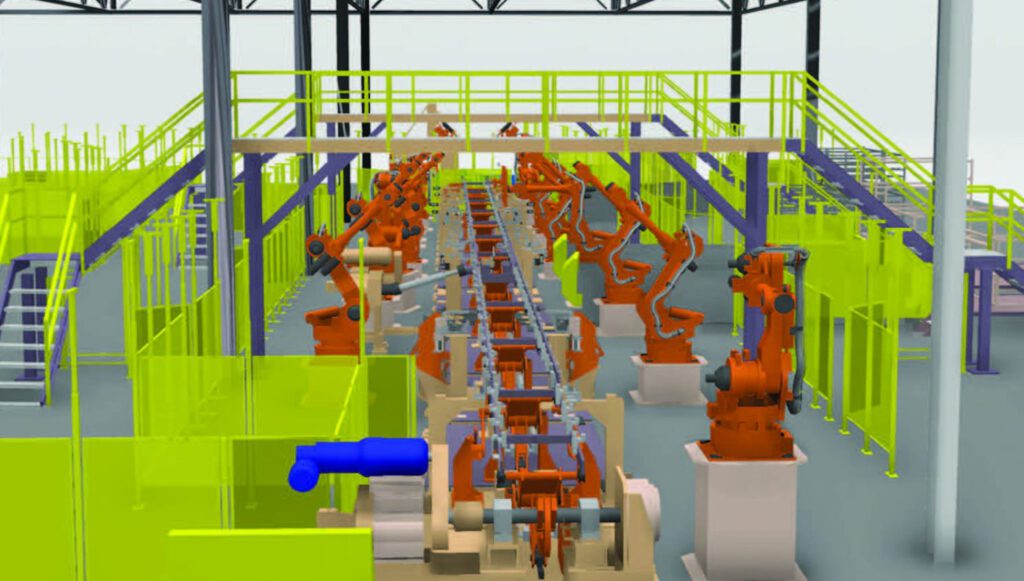

The DELMIA 3DEXPERIENCE plant layout and factory flow solutions enable industrial engineers to create a realistic, model-based representation of the shop floor and to simulate production flow. These 3D solutions allow users to virtually validate the factory layout and manufacturing processes to identify and resolve bottlenecks even before the production line exists.

Plant Layout

The plant layout solution allows engineers to create a 3D model-based virtual factory layout that contains all assembly tooling, facilities, equipment, workers, and robotics. Engineers can use a 2D drawing to position and manipulate these resources in 3D allowing for a user-friendly, fast, and efficient layout definition. Standard resources, like conveyors and shelving, can be parameterized and inserted onto the plant layout from a standard catalog. The resources placed on the plant layout are structured in the specification tree to feed downstream systems. Because this data is stored within the 3DEXPERIENCE platform, the layout data is accessible to cross-functional teams and is up to date with the latest changes. This collaborative environment allows for earlier discovery of issues with the plant layout.

Factory Flow

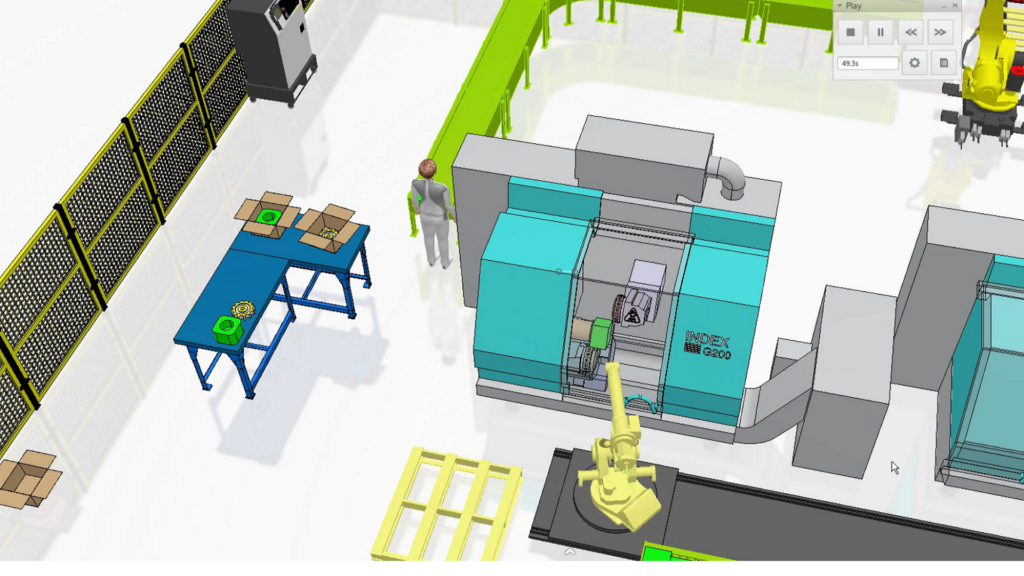

The factory layout can then be used to create discrete event assembly simulations of the factory flow that are directly linked with the 3DEXPERIENCE assembly process plans created using the DELMIA Virtual Build solution. The industrial engineers use the process plans that manufacturing engineers create and run different scenarios by defining the product arrival, processing, routing rules, buffer capacities and transfer times of the production line. With these parameters defined, the discrete event simulations can be running on a specific station, line or an entire factory. Resources such as conveyor systems and robotics can be simulated allowing for material and product flow simulation. When the simulation has been processed, the statistical data and reports can be analyzed to adjust the process plan, plant layout, or factory flow.

To watch a short factory flow simulation example created with DELMIA 3DEXPERIENCE Industrial Designer, click HERE.

Licensing

The DELMIA 3DEXPERIENCE Virtual Factory license for the plant layout solution is the Plant Layout Designer (PLA) role.

The DELMIA 3DEXPERIENCE Virtual Factory license for factory flow simulation capabilities is part of the Industrial Engineer (IEN) role and it includes the Plant Layout Designer (PLA) solution.