Over the past 15 years, many CATIA customers have incorporated 3D GD&T into their processes to varying degrees. Use cases range from simply supporting an OEM requirement, to implementing a complete paperless design-thru-manufacturing environment and anything in between. However, the fact remains that overall the adoption of 3D GD&T practices industry-wide has been very slow. In this article, we will identify some of the key contributing reasons why that has been the case and look at some exciting new developments that are sure to revitalize the 3D GD&T movement.

3 Fundamental Challenges

Most of the progression towards 3D GD&T has been in the Aerospace industry, but even so it is not as widely adopted throughout the supply chain as is commonly believed. The Automotive industry has indicated for years their desire to move towards a 3D GD&T paradigm. In both cases, deeply rooted processes, heavy use of design automation for 2D deliverables, and supplier capability/coordination challenges often have been significant roadblocks.

Regardless of the industry, we believe that there are 3 Fundamental Challenges that repeatedly inhibit the adoption of 3D GD&T:

1) There are a few tasks that are still faster (or more effectively done) in 2D

2) Someone somewhere still needs a piece of paper

- For submission to regulatory or compliancy agencies

- For use in unsafe/unclean environments

- For nth tier suppliers without 3D capabilities

3) Viewing typically requires “for purchase” software. Paper is its own “free viewer”.

Looking at the Challenges a Different Way

Traditionally, in order to address the 3 Fundamental Challenges, companies needed to be willing and able to change their business practices, develop process workarounds where needed, and sometimes make compromises. More often than not, financial limitations and deflated morale would stall an implementation before it even began.

What if we were to look at the 3 Fundamental Challenges a different way? What if there were a way to gain all the benefits of 3D GD&T and combine it with the ease of use and flexibility of a 2D drawing?

Exciting New Developments

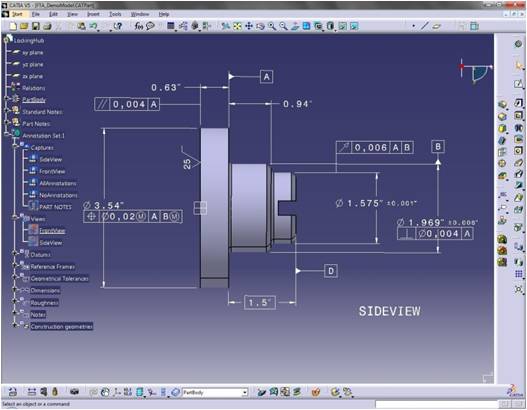

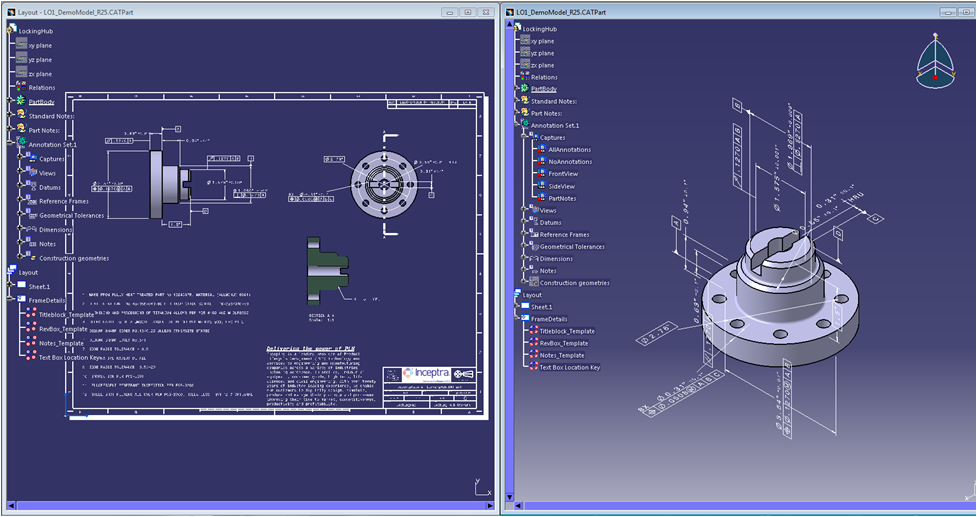

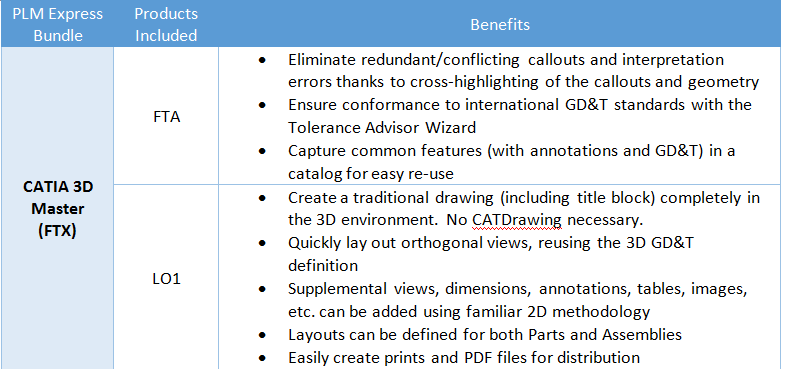

As you can see from the video above, there have been some exciting new developments and major enhancements over the last 5 releases of CATIA to one of the most under-appreciated tools within the CATIA portfolio – 2D Layout for 3D Design (LO1). LO1 complements the capabilities of 3D Functional Tolerancing and Annotation (FTA) by adding traditional CATIA drafting tools inside of the 3D space. Further, LO1 and FTA are now bundled together in the PLM Express package called CATIA 3D Master (FTX).

The CATIA 3D Master (FTX) package offers much more flexibility and options for companies to quickly take advantage of 3D GD&T. The bottom line is that FTX allows you to overcome the 3 Fundamental Challenges by using 3D GD&T for what it does best, and 2D for the rest. Because FTX enables the creation of 2D drawings within the 3D environment, some customers have been able to eliminate CATDrawings altogether, significantly reducing the total number of files to manage, while still being able to produce traditional 2D prints. Most importantly, companies who utilize FTX are able to leverage the advantages of 3D GD&T immediately without needing to change any paper-based downstream processes.

Article compiled by Jason Curtis

Director, Applications Engineering

Inceptra