In today’s increasingly competitive market, product designers must push past conventional ways of working. Innovating one concept at a time is no longer a sustainable method. And for the many industries where lightweighting has become an imperative, lightweight technology and simulation methods are now essential. These solutions efficiently drive product design that is optimized for performance while meeting demands for a reduction in energy and material requirements.

Functional Generative Design

One technology to enable product engineers to quickly achieve lightweight optimized designs is function-driven generative design software. Dassault

Systèmes’ CATIA Function-Driven Generative Designer enables non-specialists to automatically generate optimized conceptual parts from a functional specification at the push of a button.

Functional specification for this science-based generative design approach also uses key performance indicators, such as minimize mass and maximize stiffness. By varying inputs, designers can generate multiple part variations to compare and analyze. Then, manufacturing wizards help users detail design concepts based on the manufacturing process selected to produce the part: milling, casting, or additive manufacturing.

Watch this video to learn more about the CATIA Function-Driven Generative Designer solution to quickly achieve lightweight optimized designs while increasing the number of concepts evaluated:

Function-Driven Generative Design Webinar (6m36sec)

Unified Digital Platform

Another technology to enable efficient and cost-effective lightweight engineering is the use of a unified digital platform that provides a digital thread that connects, integrates and intuitively captures design, materials, and manufacturing. Without a platform for digital continuity, it is often cost-prohibitive to explore optimized parts due to the difficulty of collaborating across product development disciplines.

Because of the seamless integration across all disciplines within Dassault

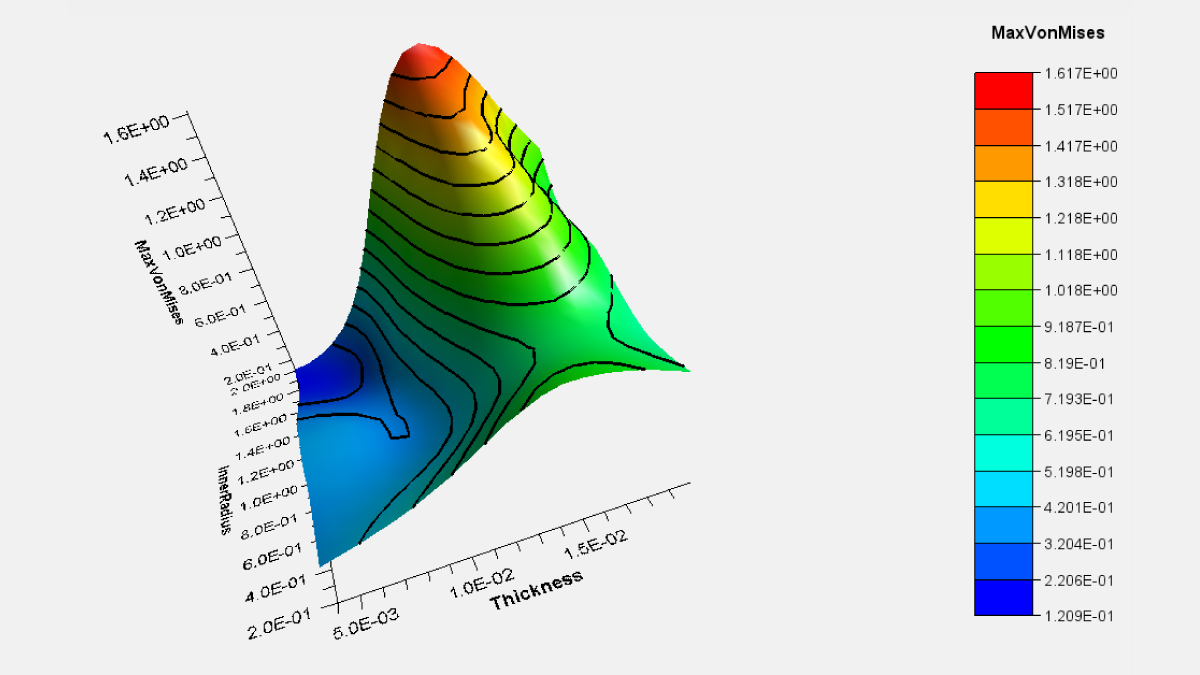

Systèmes’ 3DEXPERIENCE platform, the part generated using CATIA Function-Driven Generative Designer can then be comprehensively refined, validated and completed collaboratively and in context. Simulations can be run to ensure part strength and deformations are within tolerance. “Real” geometry can be rapidly created using integrated modeling tools to create manufacturable models for either traditional or additive manufacturing processes. View the results in the design review to help choose the best solution to fit your needs.

Digital continuity means no loss due to data translation, using solid geometry throughout for quick updates if the design changes. Using the 3DEXPERIENCE platform, continuity is maintained throughout the entire process: from design, simulation through to manufacturing.

Lightweight Engineering Solution Highlights

Dassault Systèmes’ CATIA Function-Driven Generative Designer on the 3DEXPERIENCE platform offers the following advantages for lightweight engineering of products:

- Increase productivity through an integrated set of lean and flexible process-driven capabilities

- Intuitive Workflow Assistant guides each step

- Model or import and de-feature data from any CAD system

- Capture all functional specifications: loads, boundary conditions and connections

- Extensive optimization capabilities: optimize for mass, stiffness or frequency, with displacement, stress and manufacturing constraints

Other Lightweight Engineering Solutions

Keep an eye out for future blog posts that will cover additional lightweight engineering solutions:

- Composites design, simulation, and manufacturing

- Additive manufacturing