Allows the composites operator to automate the creation of the laser projection program to be used by laser projector systems such as Virtek, Assembly Guidance, LAP, LPT, SL Laser, etc. Once the CATIA Composites model is digitally defined in the composites workbench the engineer can simply choose the laser projection system they would like output for and generate the desired laser projection output to be read natively by the shop floor laser system.

Typically laser systems have their own shop floor software that is equivalent to a low end CAD system. If you do not use the CATIA Composites Laser Projection software then the composites engineer would need to export IGES or STEP geometry of the tool surface, each individual ply and then recreate the laser projection program from scratch. Other manual interactions would be adding text, seed point, seed curve or marking geometries. If there is a CATIA design change you will need to start over again.

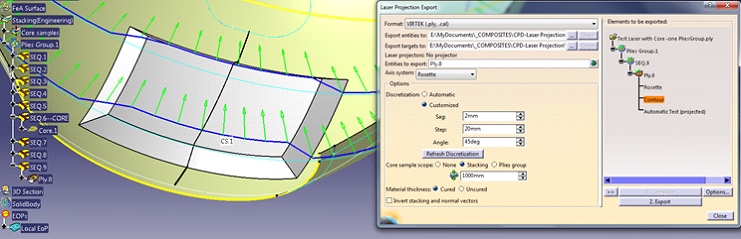

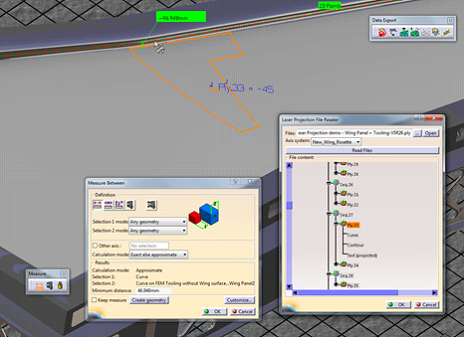

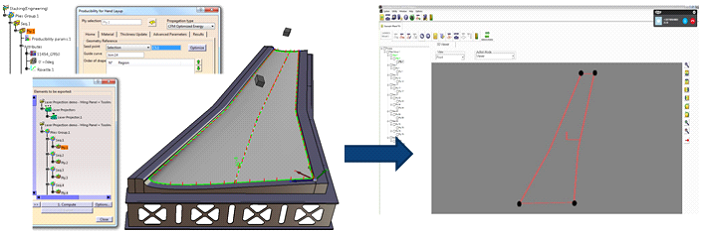

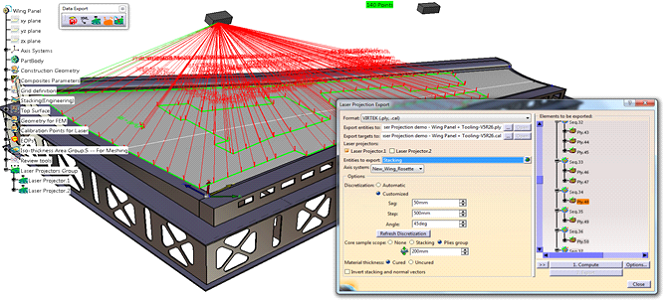

The output of a laser projection file is a very simple process after the plies have been defined:

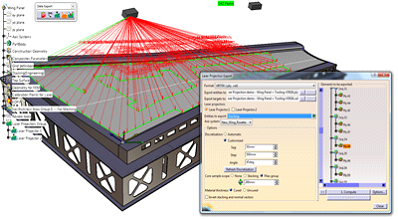

⦁ Define your laser projector location(s) and target points so you can ensure the tool is completely covered by the range of the projector.

⦁ If complete coverage is not possible you can add additional lasers or adjust the projector or tool location.

⦁ Choose the desired plies for projection.

⦁ Set the discretization level of laser points.

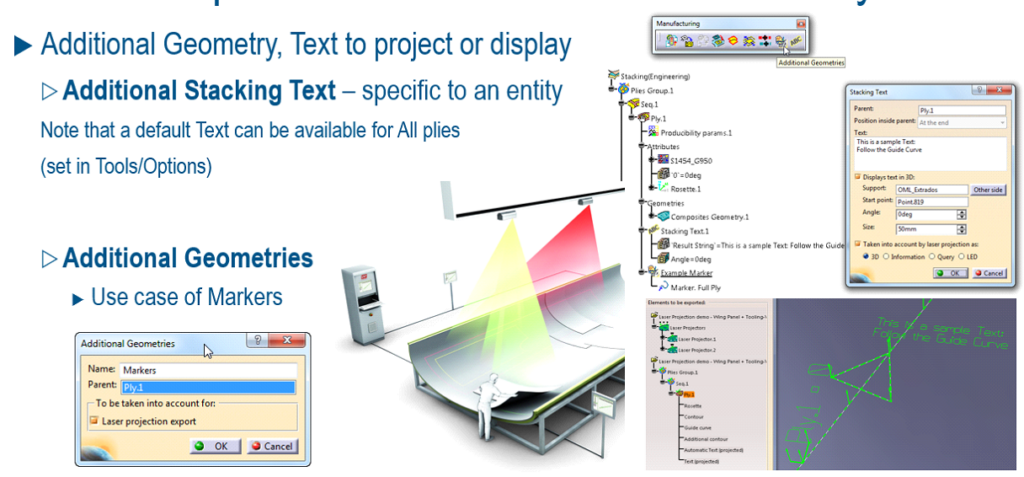

⦁ Set optional settings such as core sampling for thickness adjustment, text, parameters and additional projection geometry.

⦁ Export the files readable by laser projection hardware.

Laser projection software is available in both CATIA V5 and 3DEXPERIENCE.

⦁ CATIA V5 – Composites Laser Projection – https://www.3ds.com/products-services/catia/products/v5/portfolio/domain/Mechanical_Design/product/CLA/

⦁ 3DEXPERIENCE (on cloud / on premise) – Composites Laser Projection Operator – https://www.3ds.com/products-services/catia/disciplines/composites-engineering/tag/112-5695/

Values of CATIA Composite Laser Projection:

⦁ Laser output is direct from the CATIA Composite stacking and includes the positioning of the vectors at the thickness of the plies or core without the need for any geometry creation.

⦁ Ability to add lasers projectors in the work cell so you can see if you have coverage on the tool.

⦁ Simple to use user interface and ability to preview the laser program.

⦁ Ability to read legacy laser programs into any CATIA session to visualize and overlay them on a tool.

⦁ Projection open geometry, seed points, seed curves, etc.

⦁ Projection of stacking text.

⦁ Support and collaboration with many laser providers.

⦁ Licenced using DSLS licensing mechanism just like any other standard CATIA product.

A video of the CATIA Composites Laser Projection process.

Article compiled by Todd Wigglesworth

Senior Application Engineer

Inceptra