How do you estimate the cost of manufacturing a composite part? There are many aspects to the process, so it can be trickier than a simple machined part.

With the prevalence of composite parts on many recent projects, the government along with a consortium of industry leaders, developed an accurate composite part estimation tool. This tool was originally developed to help OEMs know if supplier estimates are accurate. However, this application is now available to the entire supply chain, from the OEM on down, allowing one common composite part estimation’ language for all parties.

The estimation tool ensures that all estimates are managed via a single estimation solution:

- Ensures Consistency

- Simplifies Training

- Reduces the effort needt to manage and maintain the estimation environment

- Provides realistic cost estimates for labor, material, tooling, set-up, and re-work

- Identifies costs drivers early in the design process

- Evaluates parts, processes, and assemblies

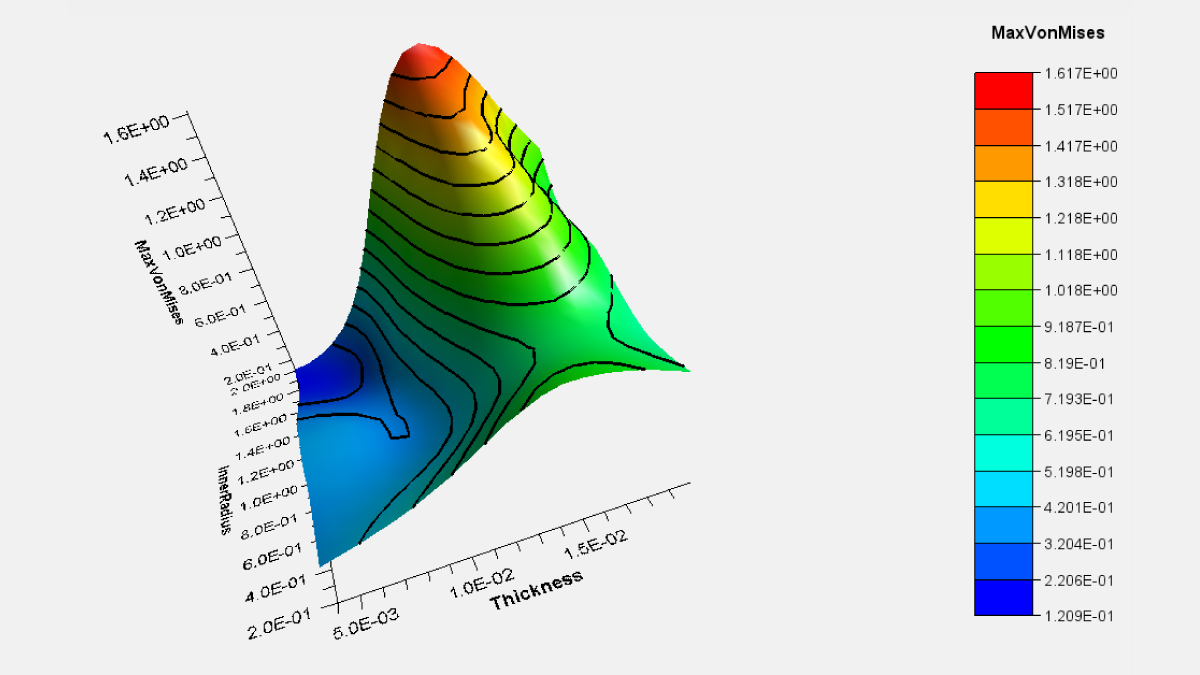

- Enables users to test, manage, and optimize manufacturing and assembly costs and risk trade-offs

- Assesses both productivity and efficiency

- Provides an objective basis (“should-cost” model) for evaluating supplier estimates

From the OEM perspective, the estimation tool enhances the procurement managers supplier negotiations and maximizes profitability through the optimization of different critical parameters, such as selection of optimum materials, manufacturing processes / operations, set-up and tooling amortization, lot sizes and automation levels.

From the supplier perspective, the estimation tool is absolutely critical for winning contracts and remaining profitable. The estimation tool provides a consistent method to estimating the cost of the composite part with little effort.

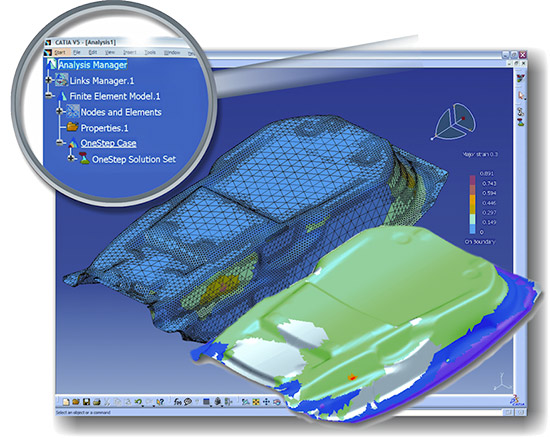

The CATIA embedded estimation tool goes way beyond the typical material cost estimation. The process libraries taken into consideration include:

- Part shape

- Build-ups and cores

- Materials and resins

- Material cutting and bagging processes

- Consumable materials

- Hot-ply forming, curing, and trimming

- Other aerostructure-specific fabrication and assembly processes